Dental lab

with digital technology

The digital “drilling” technology (“frez” technology)

Traditionally the dental technician would make a wax mould for the crown and cast it from metal.

Metals melt between 800 and 1400 Celsius. Often during the casting process the metal may oxidize and bubbles can be formed.

This technology has lots of hidden mistake possibilities. (or; This technology may hold the possibility of many mistakes.)

In an industrial way it is possible to produce homogeneous metal and zirconium blocks without oxidation which will be used in our lab as raw material for crowns and bridges with a special digital drilling technology.

Virtual Tour – Dental Lab

CAD/CAM Technology

In our lab we use CAD/CAM technology to create the frame of the prosthetic replacements.

CAD

CAM

Contact us

We are glad to help you.

The process

1. Step

The mould will be scanned with a 3D scanner. This machine is able to use laser or white light. Both types can be found in our lab. Scanners use the reflection of the light to create the objects’ solid 3D shape. Commercial 3D scanners have accuracy between 5 and 20 μm. It is also very important to mention the angle between these two cameras. Reducing the angle, deep cavities can be created, or the mould taken by the dentist can be made.

2. Step

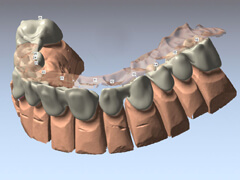

The lab technician designs the frame of the prosthetic replacement with a specialized 3D scanner created for dental lab use. This can be a crown, section of a bridge, a telescopic crown, a full crown, inlay, onlay, a press ceramic crown, a unique structure or a bar unit (pier). The software automatically outlines the preparation line and then makes a suggestion for the shape of the frame which naturally can be overwritten or modified. The ready model will be exported in a stl format and later in the process with the special digital, computer guided drilling machine it will be finalised.

3. Step

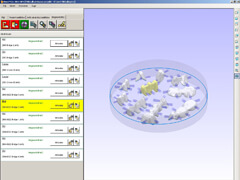

In the next step another specific software will be used to put the previously created 3D model to a raw material block used by our practice and calculate the necessary tool path for the milling machine. The final product is an NC (Numerical Control) program which can be run on the milling machine.

4. Step

The milling machine (has 5 shafts) runs the NC program which drills out the frame from a material chosen by us.

Contact Us

Healing is not just our job, but our life and our profession.

Our clinic in Hungary is nowadays one of the the best equipped private dental clinic, where we use the most advanced technologies for operations, conservative treatments and dental technology.